As global parents, schools, and brands continue to raise their expectations for children’s food safety, product quality, and design, the custom kids lunch box is no longer just “a container for meals.” It has evolved into a core product that integrates safety compliance, brand identity, and user experience.

When a company is planning to establish their own brand, enter the school supply channels, or expand cross-border markets, to them for many times how to select a reliable kids lunch box manufacturer.

So the key question is:

How do you choose a kids’ lunch box factory that is truly suitable for long-term brand cooperation?

This article provides a professional, educational perspective and combines the practical experience of Xinghui Plasticware, a Chinese plastic product manufacturer, to offer a clear and actionable evaluation framework.

Why Does Factory Selection Determine the Success of a Kids Lunch Box Project?

Kids lunch boxes are products with dual attributes: food-contact items and children’s products, which naturally come with the following characteristics:

- High safety standards (FDA, LFGB, CPSIA, BPA Free, etc.)

- Bulk-oriented purchasing rather than small retail orders

- Buyers prioritize stability and long-term supply capability

- Brands often require custom colors, logos, structures, or packaging

⚠️ If the wrong factory is selected, common issues include:

- Incomplete certifications, preventing market entry

- Unstable materials, affecting food safety and brand reputation

- Slow sampling and inefficient communication, delaying product launch

- Unreliable lead times, disrupting school or distribution channels

Therefore, choosing the right Custom Kids Lunch Box Manufacturer is essentially about reducing long-term brand risk.

5 Key Dimensions to Evaluate When Choosing a Custom Kids Lunch Box Factory

1️⃣ Food-Grade & Children’s Product Compliance Capability

This is the top priority.

A qualified kids lunch box manufacturer should be able to provide or support:

- FDA compliance (U.S. food-contact materials)

- LFGB standards (EU/Germany food-grade regulations)

- CPSIA compliance (U.S. children’s product regulations)

- BPA Free testing

- Third-party test reports (SGS, TÜV, etc.)

⚠️ The key is not whether testing can be done, but whether the factory has long-term experience and deep familiarity with different market regulations.

2️⃣ Real Customization Capability — Not Just Private Labeling

Many factories claim to offer OEM / ODM services, but in practice only provide:

- Color changes

- Logo printing

A truly mature custom kids lunch box manufacturer should offer:

- Mold development and structural optimization

- Professional material recommendations (PP, Tritan, food-grade plastics, etc.)

- Design experience tailored to children’s usage scenarios

(leak-proof, easy-open, impact-resistant)

- Customized packaging, instruction manuals, and multilingual labeling

3️⃣ Complete Product Line to Support Brand Expansion

For brands, lunch boxes are rarely the only product.

Factories with a broader product portfolio are better suited for long-term cooperation, such as:

Xinghui Plasticware is exactly this type of comprehensive Chinese manufacturer, helping brands evolve from single-product cooperation to full product-line supply.

4️⃣ Familiarity with B2B, School, and Brand Cooperation Models

Unlike retail customers, schools and brand clients focus more on:

- Lead time stability

- Batch consistency

- Complete documentation (testing reports, certifications, labeling)

- Efficient and professional communication

Factories with strong B2B experience can anticipate risks early, rather than reacting only after problems arise.

5️⃣ Willingness to Think from a Brand Perspective

A truly reliable manufacturing partner does more than produce orders. They will:

- Identify compliance risks during the design phase

- Recommend cost-effective material solutions

- Ensure packaging and labeling meet target market regulations

- Conduct thorough testing and sample confirmation before mass production

Only factories with this mindset are suitable for long-term strategic cooperation.

Why Are More Brands Choosing Xinghui Plasticware?

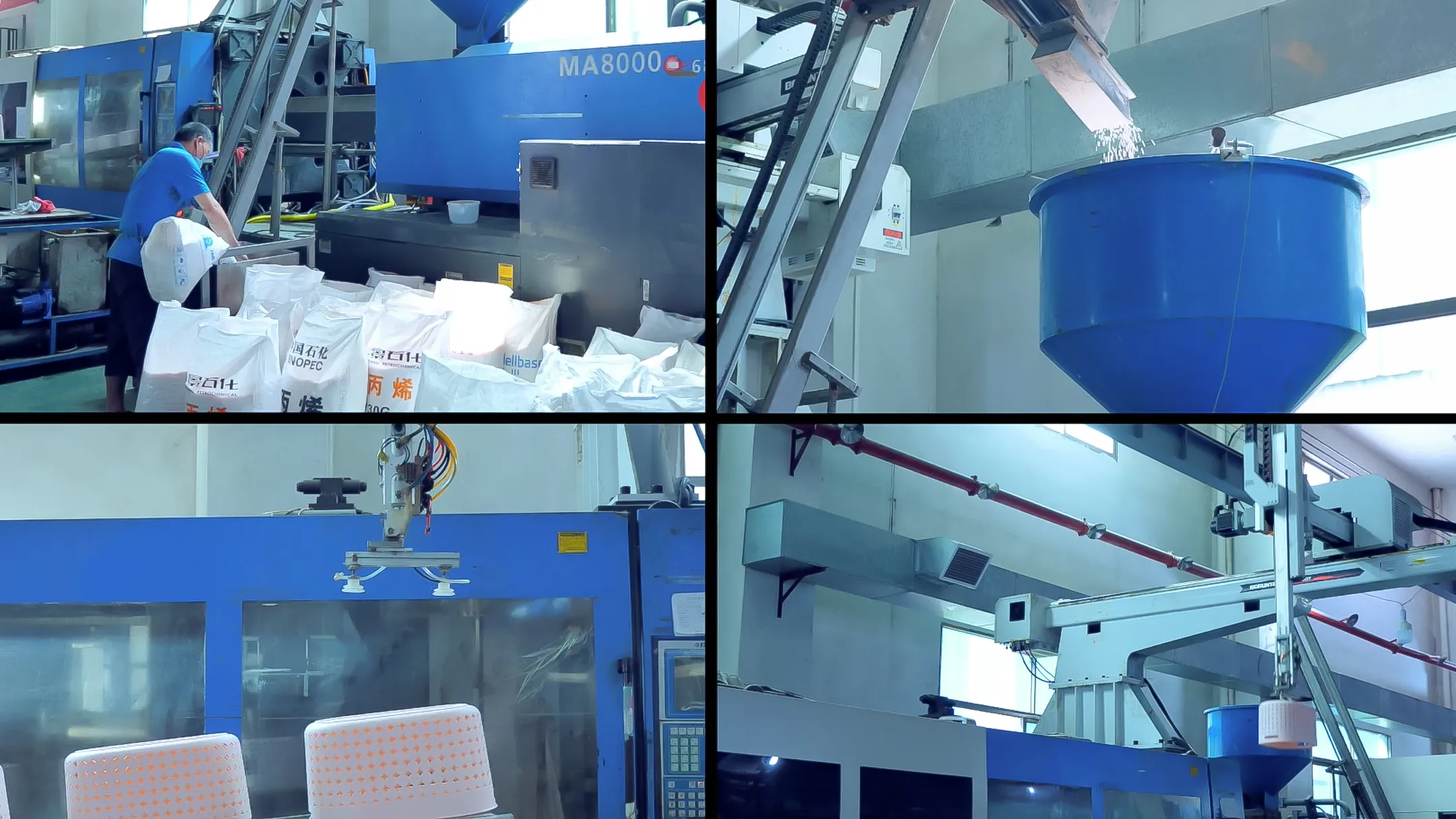

As a China-based plastic product manufacturer and wholesaler, Xinghui Plasticware has long focused on the R&D and production of food-contact plastic products. Its core strengths include:

✔ Wide Product Range for Children & Household Scenarios

- Kids lunch boxes / bento boxes

- Food storage containers

- Portable storage products

- Kitchenware

- Drinkware

✔ Strong Understanding of Global Safety Requirements

- Support for FDA, LFGB, CPSIA, BPA Free testing

- Ability to work with third-party testing agencies

- Familiarity with North American, European, and school procurement standards

✔ OEM / ODM Customization Support

- Logo, color, and structural customization

- Custom packaging and instruction manuals

- Stable mass production with controlled lead times

✔ Well-Suited for Brand & Bulk Buyers

- Serving brands, wholesalers, and school projects

- Clear communication and standardized processes

- Focus on long-term partnerships rather than one-off orders

Conclusion: Choosing the Right Kids Lunch Box Factory Is the First Step to Brand Success

In the children’s products industry, safety is the baseline, stability is the core, and professionalism is the long-term competitive edge.

Far more efficiently than just trial and error over and over, you´d be wise to team on your first production with a factory that knows products, compliance and brand building inside out.

If you are looking for a reliable Custom Kids Lunch Box Manufacturer,

If you want to customize safe, compliant, and child-friendly lunch box products for your brand,

Xinghui Plasticware is a partner worth engaging in deeper discussion.

👉 Contact Xinghui Plasticware today to request product catalogs, customization solutions, and testing support—so your kids lunch box project starts on the right path from the very beginning.